Trozon Industries Pvt Ltd adheres to rigorous standard operating procedures to ensure top-tier quality for every order. Our in-house quality checking team employs advanced machines and software integrated into our database, meticulously assessing tile parameters and surface qualities during production. After production, we conduct comprehensive checks, including assessments for late movement and curvature of tiles. Our team is empowered to reject materials that do not meet client-committed parameters, ensuring our products consistently exceed expectations in terms of quality and reliability.

Additionally, our company actively solicits client feedback through detailed forms that comprehensively assess essential aspects of our products and services. Top management meticulously evaluates these responses, underscoring our steadfast commitment to customer satisfaction. With consistently high ratings for product quality, we proudly accumulate numerous positive feedback forms from our clients. Moreover, our commitment to strict and reliable quality control is reinforced by our policy of no reinspection, ensuring stringent adherence to our quality standards.

Our brands, Trozon and Tiles Carrelage, command high esteem in global markets and are exported to discerning destinations worldwide. We maintain rigorous adherence to country-specific quality norms, leveraging decades of experience among our skilled quality inspectors to ensure consistent standards across all operations. Quarterly quality reports undergo meticulous review by top management, providing valuable insights for ongoing enhancement in future orders. Our systematic approach and extensive experience establish us as the preferred choice for clients who prioritize uncompromising quality. Here’s an overview of key operational parameters of our system.

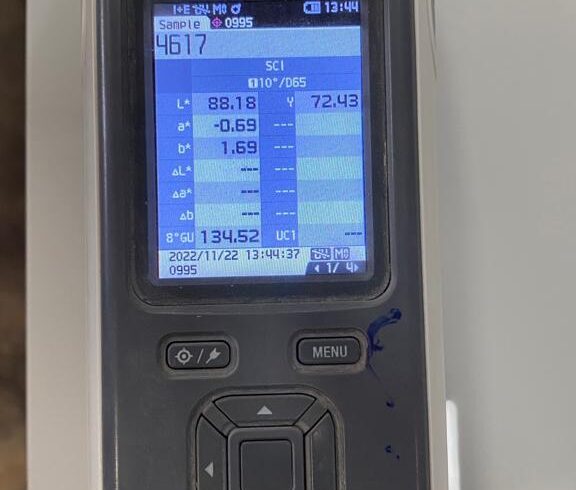

A whiteness test for porcelain tiles evaluates the surface’s brightness and lightness, serving as a crucial quality control measure in tile manufacturing. This test examines how the tile’s surface reflects light, directly influencing its perceived whiteness and ensuring uniformity and quality across the final products.

A whiteness meter, also referred to as a colorimeter or spectrophotometer, is utilized to conduct the test. It measures the light intensity reflected from the tile’s surface across various wavelengths. This ensures manufacturers, like Trozon, maintain superior whiteness compared to others, crucial for meeting stringent aesthetic and quality standards. In industries such as architecture, interior design, and construction, where tile visual appeal is paramount, this distinction is particularly vital.

The stain test for porcelain tiles assesses their resilience against staining from various substances such as liquids and oils. This test is essential in environments where tiles are likely to encounter these materials, ensuring they maintain their aesthetic appeal and cleanliness by evaluating their ability to resist absorption. Additionally, our company conducts marker testing to assess whether tile can resist marker stains and whether these stains can be easily removed afterward.

The test involves selecting a variety of substances commonly encountered in everyday settings, such as red wine, tea, coffee, ketchup, oil, ink, and others. This selection aims to simulate real-life scenarios where these substances could potentially stain the tile’s surface.

The deviation in length and width tests for porcelain tiles assess the tiles’ dimensional accuracy and consistency, ensuring they meet specified size requirements and adhere to industry standards. These tests measure permissible variations in dimensions compared to the intended sizes, guaranteeing precise and uniform tile production.

We employ precision measuring instruments such as calipers, micrometers, or digital tools to perform tests on tile dimensions like length and width. These tests identify any deviations from specified size requirements, enabling us to promptly address and correct discrepancies. By ensuring tiles meet exacting standards through these tests, we uphold quality and consistency, meeting the expectations of architects, designers, and end-users for optimal performance in various applications.

Deviation in thickness refers to the variation or difference in the thickness of porcelain tiles within a given batch or lot. Porcelain tiles are manufactured to certain standards and specifications, including their thickness. However, due to the inherent nature of manufacturing processes and materials, there can be slight variations in the thickness of tiles even within the same production run.

Deviation in thickness is determined using precise tools like calipers or digital thickness gauges. This process entails measuring the thickness of multiple tiles within the same batch at various points on each tile and then calculating the range of thicknesses observed. It’s essential to note that deviations in thickness are commonly specified as tolerances. For instance, a tile might be required to have a thickness of 9mm with a tolerance of ±0.4mm. This means the actual thickness of the tile can range from 8.6mm to 9.4mm and still be considered acceptable according to standards.

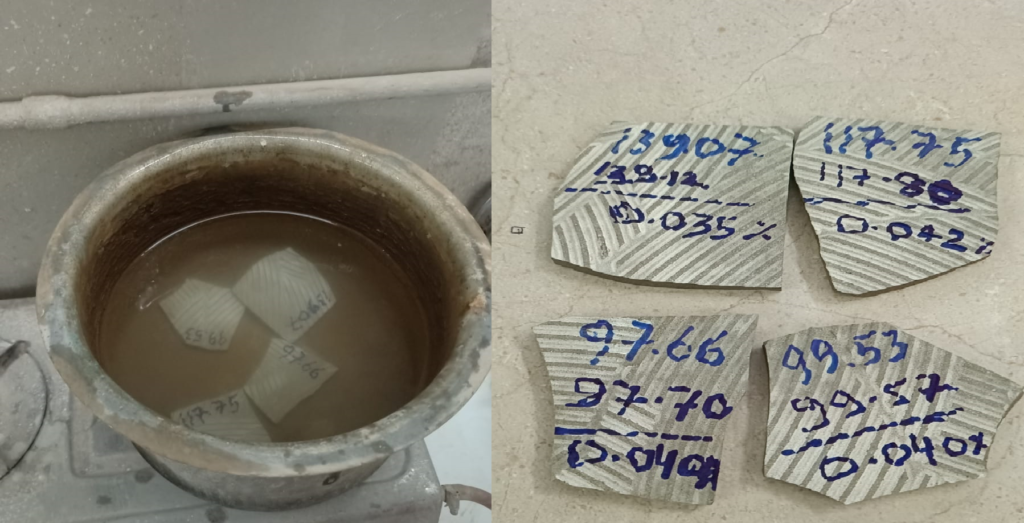

Water absorption inspection following tile production is a critical quality control measure. This step involves assessing the tile’s capacity to absorb water, which is crucial in determining its suitability for various applications. Tiles with low water absorption rates are typically preferred for areas such as bathrooms or kitchens, where moisture resistance is essential. This inspection ensures that the tiles meet the necessary standards for their intended use.

At our company, we place a strong emphasis on water absorption because tiles with low water absorption tend to be more durable and robust over the long term. We conduct regular water absorption tests to evaluate the quality of tiles with each order, ensuring consistency and reliability in our products. This commitment to quality control helps us deliver tiles that meet high standards of performance and durability for our customers’ needs.

Trozon Group places a strong emphasis on maintaining consistent bending in tile production. Utilizing the latest Planar machine, we rigorously evaluate the bending characteristics of our tiles. Bending is a crucial aspect in the tile industry, and we prioritize it with utmost clarity and focus. In addition to machine assessments, our company conducts manual checks to verify the accuracy of the machine readings. According to industry standards, the acceptable bending range is within +-0.50, and we ensure that our tiles consistently meet these parameters.

At Trozon, we are committed to producing tiles that are not only aesthetically pleasing but also technically robust. This dedication to quality ensures that our tiles possess both visual appeal and structural integrity, meeting the high expectations of our customers and industry standards alike.

The glossiness test assesses the quality of porcelain tiles by measuring how well their surfaces reflect light. Glossiness specifically refers to a surface’s ability to uniformly reflect light in a mirror-like manner, giving it a shiny and polished look. This test is essential for evaluating both the aesthetic appeal and functional performance of porcelain tiles.

Glossmeter is employed for this purpose, designed to precisely measure gloss and shine on porcelain tiles. It operates with a light source that directs light onto the tile’s surface at a defined angle, while a receiver quantifies the reflected light. Testing glossiness is integral to quality assurance in porcelain tile manufacturing, ensuring consistent visual standards and confirming that tiles achieve the desired level of shine.

The flexural strength test for porcelain tiles is a critical mechanical evaluation that measures the tile’s ability to withstand bending or flexing without breaking. This assessment is essential for assessing the tile’s structural integrity and its suitability for various applications, especially where tiles may experience bending stresses, such as floors or walls. The procedure involves applying a controlled load to a supported tile specimen until it fractures. The Modulus of Rupture (MOR) value is a key parameter for assessing the strength of the tile.

Position the tile specimen on the bending fixture with its glazed surface facing upwards. Ensure that the support points are accurately spaced beneath the tile, and place the loading point precisely at the midpoint between these supports. Apply a steadily increasing force or load to the center of the tile using a hydraulic or mechanical testing apparatus at a controlled rate. This ensures uniform stress application to the tile throughout the test. Continue the test until the tile specimen fractures. Record both the moment of fracture and the corresponding applied force. This fracture point indicates the maximum load capacity of the tile before it fails, providing critical data about its strength characteristics.

The computed flexural strength value offers valuable insights into the tile’s capacity to withstand bending forces, crucial for assessing its conformity to specified standards for intended use. Tiles demonstrating higher flexural strength values typically exhibit enhanced durability, making them suitable for demanding environments, ensuring prolonged performance and safety.

Trozon Industries Pvt Ltd is renowned for its longstanding commitment to quality maintenance methods and rigorous quality control measures. The procedures outlined above serve as a testament to our company’s dedication. At Trozon, we maintain a master file for each order from every client, ensuring consistent tile shades across repeat orders. Emphasizing both pallet and stripping quality helps prevent breakage, further ensuring product integrity. Our loading processes are handled by experienced teams to minimize cargo mishandling. Clients can refer to the last page of our catalogues for more details on our stringent quality parameters and standards.

WhatsApp us